A team of researchers at Texas A&M University has developed the concept of a toolkit that would allow builders to create structures via 3-D printing using local soil as the building material. In their paper published in the journal Frontiers in Materials, they outline their ideas and possible ways to create such a toolkit, and describe a test project they built.

Concrete is one of the most basic ingredients used to build both large structures and walkways. Its use, however, contributes to global warming—concrete manufacture releases CO2. The researchers note that prior research has shown that as much as 8% of global CO2 emissions can be traced back to concrete production. They also point out that it is difficult to get rid of the concrete used in a structure or walkway once its useful life has ended. They suggest there is a better way—using local soils to create replacement building materials.

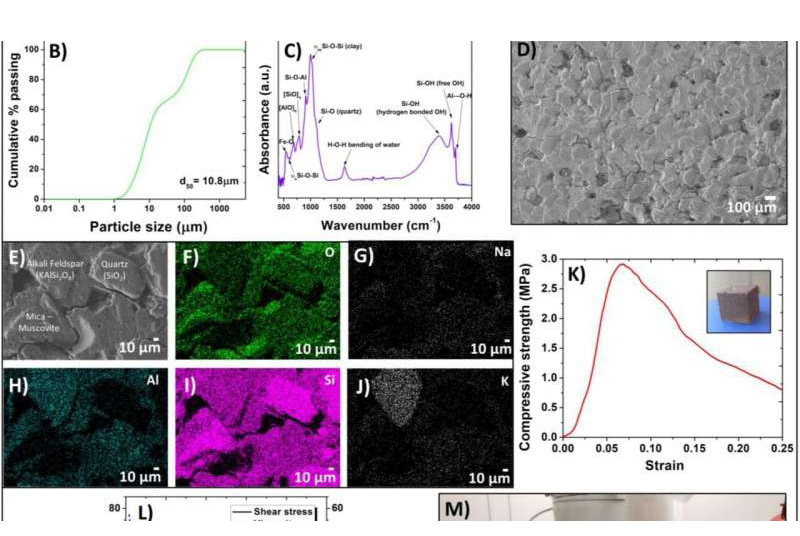

The researchers note that many ordinary soils, particularly those with high clay content, could be processed to produce a material with applications similar to concrete, i.e., that can be poured as a semi-liquid that hardens in place. They further suggest that such materials could be produced on-site using local soils and put into place using very large 3-D printers. For such scenarios to be realized, they propose the idea of a toolkit that could be used to produce concrete replacement materials using local soils. Such a toolkit would have a means for analyzing a local soil supply and then producing a recipe for a material that could be poured like concrete and harden in place.

To demonstrate their idea, they collected soil from the back yard of one of the researchers and devised a recipe for it. They then used the recipe to create a mix using the soil sample, sodium silicate and an alkaline catalyst. Next, they used the mix they created to create a small walled-structure in their lab. They acknowledge that the materials they have made thus far are best suited for nonstructural parts of a building, such as fa?ades, but believe they will soon be able to produce materials suitable for general use.